Pilot trial Services

Extrusion Coating - Spesifications

A unique pilot line for the creation of new packaging material innovations.

Extrusion coating

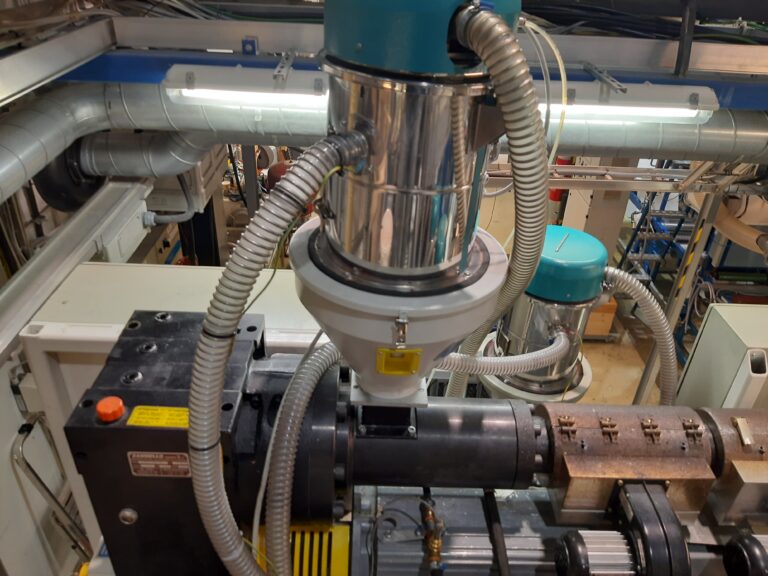

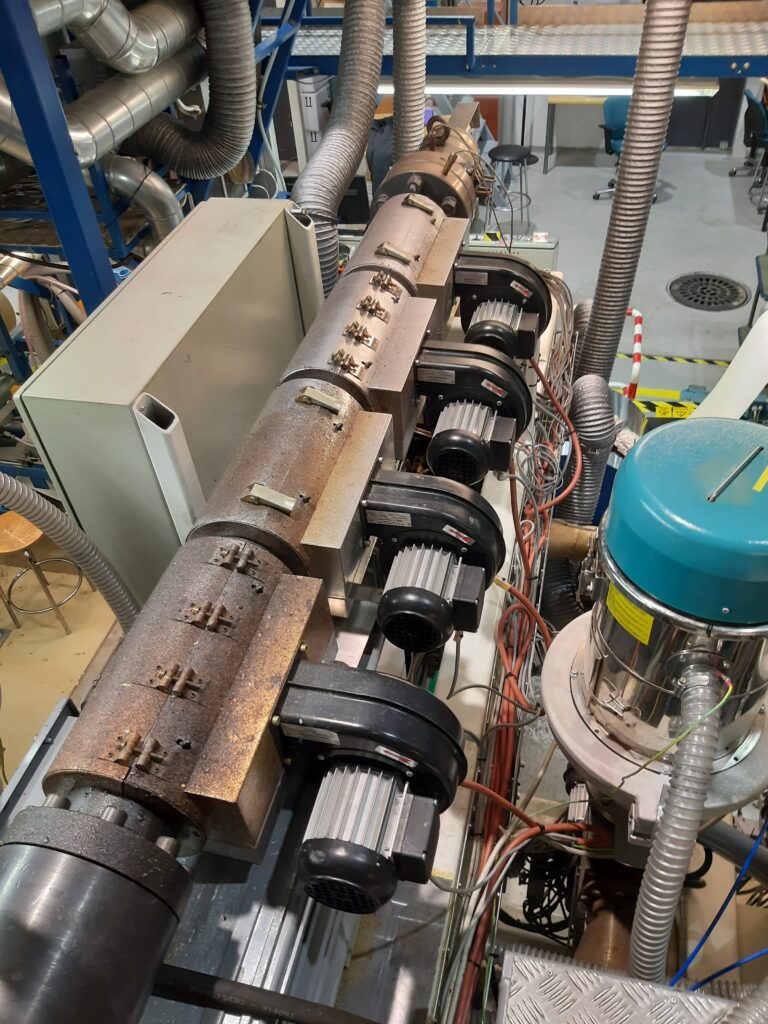

- Extruder A

- Diameter 60, L/D ratio 30

- Max output 90 kg/h LDPE (depending on the polymer)

- Polymer melt temperature and pressure measurement

- Hopper loader

- Extruder B

- Diameter 40, L/D ratio 24

- Max output 30 kg/h LDPE (depending on the polymer)

- Polymer melt temperature and pressure measurement

- Hopper loader

- Extruder C

- Diameter 30, L/D ratio 25

- Max output 20 kg/h LDPE (depending on the polymer)

- Polymer melt temperature and pressure measurement

- Hopper loader

- Extruder D (normally in encapsulation use)

- Diameter 30, L/D ratio 25

- Max output 20 kg/h LDPE (depending on the polymer)

- Polymer melt temperature and pressure measurement

- Hopper loader

- Die

- Cloeren EBR III A

- Internally Deckled Extrusion T-type Die

- Lip Heaters

- Edge Encapsulation System

- Feed block

- Cloeren VG 5-layer Dual Plane Feed block

- Streamline Manifold

- Selector plugs

- Web - A-A-A-A-A D/D

- Web - B-B-B-B-B D/D

- Web - A-A-A-B-B D/D

- Web - B-B-A-A-A D/D

- Web - B-C-A-A-A D/D

- Web - A-A-C-B-B D/D

- Web - C-A-A-A-B D/D

- Web - B-C-D-A-A A/A

- Web - B-D-C-D-A A/A

- Web - C-D-A-A-B B/B

Surface treatment

- Corona

- Vetaphone Corona-Plus

- Treatment power max. 4 kW

- Ceramic electrodes

- Post corona

- Softal 50100

- Treatment power max. 1,5 kW

- Metal electrodes

- Atmospheric plasma

- Vetaphone Corona-Plus

- Treatment power max. 2,0 kW

- Ceramic electrodes

- Argon and Helium, plus their mixtures with Nitrogen

- Treatment width 380 mm

- Flame

- Hill GmbH, type EF 75-1 (Burner CE62-500)

- Heat output max. 50 kW

- Gas supply propane

- Movable flame unit and adjustable air gap

Contact

Marikki Laamanen

Tel. +358 40 849 0991

firstname.lastname@kcl.fi